Custom Ampules in the Lab

What are Ampules and why use them?

Custom ampule-filling is one of Sarchem’s most popular services. This post will explore why ampules are so popular and the role can they serve in a variety of applications.

First, the basics: Ampules are similar to vials and were developed in the 1500s to be used for medicinal purposes. Ampules are able to preserve the contained material by extending the shelf life of the liquid or solid sample. Ampules are typically made from borosilicate glass and can be clear or amber, with the latter used for light-sensitive samples. Glass, as opposed to plastic, is used for its resistance to chemicals and liquid solutions, heat sterilization — as well as its near-unlimited life span. Pre-scored ampules have a tightened stem for opening, removing the need for filing. Because both straight-stem and funnel-type ampules are open, sterilization is required prior to filling.

Clients use Sarchem’s ampules and custom ampules to extend the shelf life of samples. Ampules are also versatile in use, as they can hold a range of materials (including compounds that are air- or water-sensitive) for varying applications in medical or analytical labs.

The Ampule Process

It is crucial that ampules contain only the compound, not dirt or air. Sarchem custom fills each ampule on a calibrated scale using sterilized syringes and fillers. To get within 5 micrograms, Sarchem painstakingly measures and fills each ampule. Besides a steady hand, the task requires a sterilized environment and limited exposure to outside decontaminants. We also inject an inert gas (such as Argon) to make sure that the material is 100% pure.

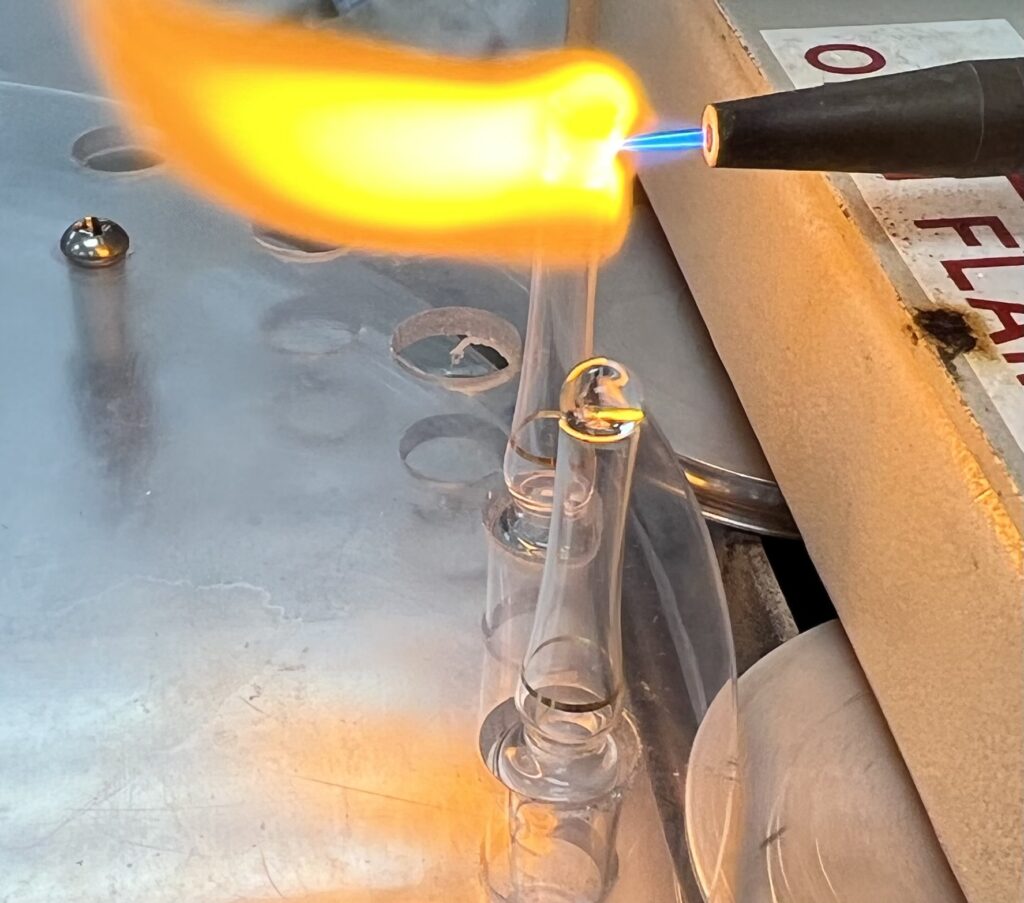

After being filled, the ampule goes straight to a belt under a flame to be sealed. Ampules can be sealed by the tip-seal method or the pull-seal method.

The tip-seal method is where the top of the glass is melted from the top. The ampule is on a belt that rotates the ampule under a flame, giving it a nice, rounded seal.

The pull-seal method melts the glass in the middle of the neck. With the glass melted, the top of the ampule is pulled off (from the neck) with a small thin glass to create the seal.

Sarchem has the equipment and know-how to implement the pull-seal method while inserting inert gas to ensure your kits will be contaminant free.

Sarchem can produce ampules for a variety of client types and sizes, including end-users that don’t require a large number of ampules. Sarchem’s custom filling ranges from 81 ampules to tens of thousands. These are carefully packed to prevent breakage or leaking.

To get a quote or discuss your ampules project and custom ampules filling, please contact us at 1-844-SARCHEM or info@sarchemlabs.com